World firsts in – CCUS for cement and AI designed wind turbines and what to do with 19,000 teabags

In this issue:

Rush on for green hydrogen tax credits in Oz

The Australian Government has just introduced a bill to its parliament to provide a tax credit of AU$2 per kilo for green hydrogen production. Supporters cite positive signalling for the hydrogen sector and point towards even more generous schemes in other countries looking to thrive in the green hydrogen market. However, the bill is not without its critics as many see it is biased towards large organisations. The rush is now on to get the bill passed in the last weeks of parliament before recess.

World’s first industrial scale carbon capture for cement

The cement industry is responsible for around 8% of global emissions but it now has its first completed, industrial scale carbon capture facility at Brevik, Norway. The facility has been built by SLB Capturi for Heidelberg Materials and is designed to capture 400,000 tonnes of carbon emissions each year.

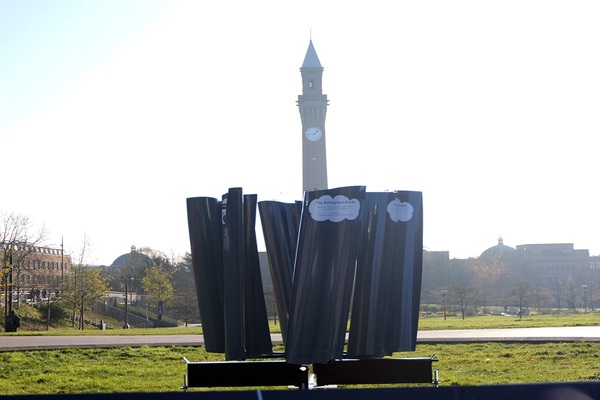

World’s first AI designed wind turbine unveiled

Known as the Birmingham Blade, after the university that developed it, the roof-top turbine is claimed to be 7 times more efficient than existing designs at low wind speeds, such as those experienced in Birmingham. We’d love to see how it would go in Wellington.

A material methane fix

Methane is far more potent than CO2 and has contributed around 15% of global temperature rise. It can be converted to usable products but the process is very energy (heat) intensive. Researchers at MIT have developed a new technology, a catalyst, that enables conversion of methane into polymers that can be used for textiles at room temperature and atmospheric pressure. However, their next step is to look at incorporating the catalyst into pipes that transport natural gas, where the polymer could work as a sealant to fix cracks, a common source of methane leakage.

Old tech into new tech – a new application for waste oil

There are several ways waste oil can be repurposed but an exciting new way has been developed by scientists from the University of Shanghai for Science and Technology and Tongji University. They have created a process to manufacture high-performance supercapacitors using waste oil as a key feedstock.

Proton battery beats lithium

Scientists at UNSW have developed an organic, proton battery that outperforms lithium. The new technology is able to store energy quickly, last longer (lasting 3,500 charging cycles) and perform well under sub-zero conditions.

600Km range heavy trucks soon to hit the market

Both Volvo and Renault have recently announced the arrival next year of electric, heavy trucks with single-charge ranges of 600Km. In both cases the extension comes from a new, electric axle that combines motors and transmission into a single unit freeing up space for extra battery capacity. Renault’s press release was keen to emphasise the availability of flexible options on battery size to optimise weight against range and charging strategies. It’s not clear when the new vehicles will be available in New Zealand.

Paint adds 12,000 Km range

That’s the claim of Mercedes engineers who have developed a PV paint for the luxury brand. The paint is non-toxic, does not contain rare earth metals or silicon, is recyclable and has a 20% efficiency rating. Under the right conditions, 12,000Km of range per year could be added from using the paint.

Did you know …….

The preferred instrument for checking carbon sequestration in wetlands is ……. the humble teabag. A team of scientists lead by researchers at RMIT have just published the results of their three-year study that covered 180 wetland sites across 28 countries. The team buried around 19,000 teabags, between 40 and 80 per site of green and rooibos teabags, at a depth of 15 centimetres. The varieties decompose at different rates and analysis against climate regions and salination levels gives clues about storage potential. The slower the decomposition, the more potential exists for carbon storage.